Reciprocating Friction Tester service|high frequency friction tester : broker A reciprocating sliding friction and wear test rig is a device used to study materials’ wear and friction properties under sliding conditions. It simulates the conditions of real-world applications such as gears, bearings, . Resultado da 21 de ago. de 2023 · Designed and published by Ali Alattas, Alilato comes in 9 distinct weights, offering a wide range of possibilities for designers and .

{plog:ftitle_list}

WEB40 78,1K. 92. 6. #ninfa #japa #pack #packs #gostosa #peituda. LIVE SEX CAMS. NINFA JAPA PACK, COMPLETO 》https://t.me/grifinpacks pictures and videos on EroMe. .

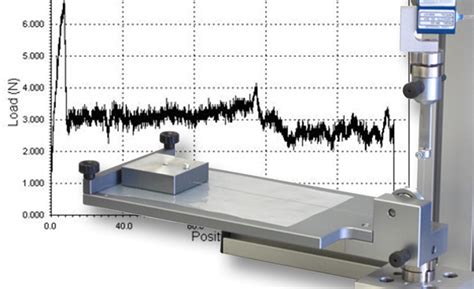

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. A reciprocating sliding friction and wear test rig is a device used to study materials’ wear and friction properties under sliding conditions. It simulates the conditions of real-world applications such as gears, bearings, .

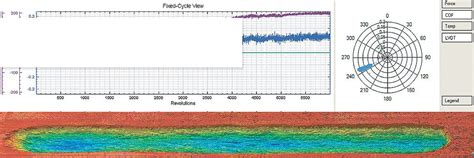

To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism.Testing and measurement of friction, wear, and material mechanical properties Tribometers and Mechanical Testers Research into materials and how materials can be changed to influence strength, integrity, or durability is an integral part .

High Frequency Reciprocating Friction and Wear Testing Machine (Diesel Fuel Lubricity Tester ) Model: HK-HFRR-001 . Heater: Heater adopts PTC ceramic chip, it features uniform heating, safe, long service life, no replacement. 6. Sample steel ball: Diameter:6 mm, Diameter:6 mm, material conforms to ANSIE-52100 28th grade steel of ANSIB3.12 .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of . Various types of tribometers are used to assess friction and wear of contacting surfaces viz. pin on disc tribometer, four-ball tester and high frequency reciprocating tribometer. The pin-on-disk tribometer is a laboratory apparatus for evaluating the friction and wear properties of different materials under different conditions of load, speed .To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .

The equipment has two forms of motion, so it includes two test modules, which are easy to replace and can meet more test requirements. Rotating module: The equipment moves in a rotating way to achieve a variety of friction contact forms and a variety of lubrication states to realize the friction simulation test between different friction pairs, with a variety of friction .

The Triboster TSf-503 is designed for computer-controlled analysis of the static and kinetic coefficient of friction (COF). The highly versatile device, with its linear reciprocating sample stage, can be used for all kinds of samples with different shapes because fixtures can be specially designed according to the sample.

2. Set the test parameter: Stroke length, reciprocating frequency, friction, test temperature and test time. It also can do the course setting to each parameter. 3. Control the mechanical part running time, it can keep monitoring the stroke length, reciprocating frequency and . 2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has . Heavy loads and fatigue wear of the contact areas between the hydraulic cylinder block and the sealing ring seriously affect the sealing performance. In order to prolong the service life of the hydraulic system, the bionic self-lubricating samples were prepared by filling SnAgCu and Ti3C2Tx (SACT) into surface biomimetic textures, and the effect of wear frequency on the .Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal-bearing test allows for evaluation of the friction over a range of relative velocities and/or loads.

MGW-02 high-frequency reciprocating friction and wear testing machine Introduction: The high-frequency reciprocating fatigue friction and wear testing machine can achieve friction and wear performance testing between materials or coatings under small contact pressure, variable frequency range, and reciprocating motion conditions.After-sales Service: 1 Year Warranty: 1 Year Type: Friction Testing Machine Maxcapacity: <1000KN Accuracy Grade: 1 Load Way: Electronic LoadPolymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are . Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004

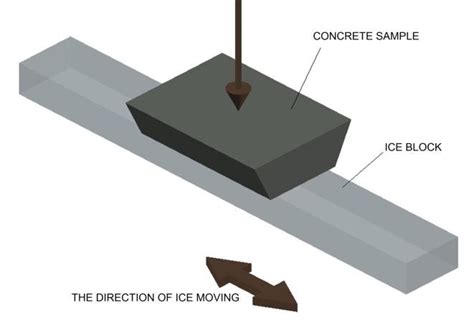

Rtec SRV Tester studies friction and wear of lubricants and grease. ASTM, DIN, ISO compliant, with wide test range. Stroke control from 5um . Dedicated SRV tester for reciprocating friction and wear analysis. SRV Test on Multi . The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .Download scientific diagram | Linear reciprocating sliding friction and wear tester. from publication: The Relationship between the Model of the Laser Biomimetic Strengthening of Gray Cast Iron .

The more usual arrangement is Fig 1 The simple reciprocating friction and wear tester 0301-679X/80/010011"05 .00 1980 IPC Business Press TRIBOLOGY international February 1980 11 Moore and Noah - Friction and wear tester pneumatic loading of the test sample, as shown in Fig 3. . We use cookies to help provide and enhance our service and .Comparative study on sliding friction and wear properties of low alloy wear-resistant steel Hardox400 and NM400 at room temperature using Retc multi-function friction and wear tester. In brief, an in-house-built tribometer was used and operated in ball-on-flat linear reciprocating test conditions with a stroke of ~1 mm at a reversing frequency of ~1 Hz. Plane polished titanium alloy (Ti6Al4V) samples were used along with 10 mm diameter counterbodies (hardened 100Cr6 steel or Si 3 N 4 ceramic) in dry or oil-lubricated .

During petroleum drilling, the reciprocating motion in the seal device leads to piston and sleeve wear, which may cause leakage of the sealing medium. Selecting appropriate materials for the piston and sleeve, along with surface modifications, can effectively prolong the seal service life of the seal. The friction and wear properties of piston and sleeve pairs of . The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat .

slip friction test

sliding friction test

Reciprocating Friction Tester. Model Name-Series. Wear Test Systems. View All View All Series. Data-Manufacturer information. . deal with customer’s needs quickly and spare no effort to always bring satisfaction with the best products and after-service based on trust and credit. In order to build a more convenient and innovative testing .

Aiming at the reciprocating motion existing in the space rolling bearing, the wear characteristics of the reciprocating friction of MoS2 were studied. The friction simulation between Fe–Ni–Cr substrate and MoS2 is simulated by mixing multiple potential functions. and came to the following conclusions: . such as gas and magnetic suspension .Description. This tester is focused on wear testing evaluation by visual inspection. The Basic Grade Type: 30, and the Type: 30S with non-staged high speed adjustment function and specified rotation number auto stop function, are available.In addition, the 2-series and 4-series specifications, where testing can be carried out a number of times under similar conditions, .

linear wear friction testing

linear friction tribometer test

high frequency friction tester

Agendamento SIGA v.2.0 . Carregando.

Reciprocating Friction Tester service|high frequency friction tester